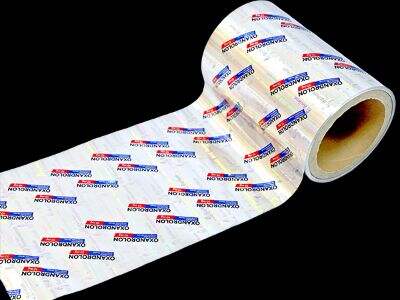

Blister Aluminium Peel & Push Foil is a better packaging solution in comparison with PVC mono which have an adhesion ten times higher than PVdC. We understands the importance of protecting medicines at Hanlin Pharmaceutical Packaging. You want pills or capsules to work well and be safe when you buy them. This is where aluminum blister packs come in. These packs also protect the medicines from things that can corrupt them, such as water and light. They are sturdy and keep everything inside safe until you want it. That’s why so many companies, ours included, use them for packaging.

Why Barriers Matter to the In-use Shelf Life of Tablets?

He also stressed that aluminium blister packs play a significant role in preserving the freshness of tablets and capsules. When drugs are manufactured, they must remain safe and effective until you take them. They can lose their potency if exposed to air, light or moisture. So they might not be as effective when you really need them, the authors said. Aluminium Blister foil packs reduce the chances of this happening, as they contain each tablet or capsule in its own pocket. This way when you open the pack only the one you need is exposed. It’s a bit like having a little house protecting each pill. That’s very good for shelf life, which refers to how long the medicine will remain effective before it expires. For example, a medicine in a blister pack can last for years. But if that bottle is unprotected, it may only last for a few months. Here at Hanlin Pharmaceutical Packaging, we spend great effort making these packs to keep your medicine as safe and effective for as period of time possible.

How do pharmaceutical blister packs protect against light and moisture?

Moisture and light is very damaging to tablets and capsules. If moisture reaches medicines, it can make them dissolve or go bad. Some of the ingredients in medications can also be degraded by light, which makes them less effective. Two major issues are avoided by using aluminium blister packs. The aluminium is a strong enough to keep water out. It’s like a shield that protects the medicines on the inside. It opens in only one section at a time so the other medicines are protected from outside air and moisture. This is crucial, because it now will enable the active ingredients to stay in place. Light is another issue. Many Foil blister packs are also constructed with light-blocking materials. That means that even if the pack is placed on a shelf and exposed to bright light over a period of time, the medicines inside will remain unharmed. When you need a higher level of protection for your medication, Hanlin Pharmaceutical Packaging is here with the simple solution. This will make sure that they are still potent and safe to use when you take your tablets or capsules.

Wholesale Where to Get Premium Aluminium Blister Packs?

If you are interested in alu blister, high quality aluminium blister packs can be found at dedicated companies who specialize in pharmaceutical packaging. One of them is Hanlin Pharmaceutical Packaging. They supply durable variety of aluminum blister pack that are widely used to safe and preserve the medicinal properties by keeping them intact. Their pouches come in various sizes and shapes, so they can accommodate multiple types of tablets and capsules. If you are looking for blister packs then make sure the company has a good repute. You can do this by searching the web for online reviews or asking other business owners who also utilize Aluminum blister packs. THis will enable you to gain access to suppliers who can give you the best packaging for your products.

The task to find high-quality blister packs can also be accomplished through trade shows and/or industry events. It is at these shows that you can meet packaging companies like Hanlin Pharmaceutical Packaging, and have a closer look at their products. You may inquire about how the packs are made and what materials are used. This is a fantastic opportunity to understand more about blister packaging technology and how it can improve your business. You can also compare between different providers and pick the one that suits your requirements. There are still good suppliers available online if you can’t go to a trade show. Many businesses have websites that feature their products, including aluminium blister packs. You can scroll through their catalogs and contact directly. Be sure to inquire about wholesale pricing when buying cigarettes in bulk can provide an economy of scale.

Why Choose Pharmaceutical Aluminium Blister Packs?

Aluminium Blister Packs are the preferred product packaging solution for tablets and capsules. One of the key advantages is that they maintain the freshness and potency of the medicine for an extended period. Aluminium is a robust material which protects the tablets from air, moisture and light. These things can hurt the drug and cause it to be less effective. With the help of aluminium blister pack, companies can also ensure the safety and potency of their products till they are consumed by the consumer. This is specially significant in the realm of pharmaceutical formulations where medicine quality is a matter of patient health.

Another benefit of aluminum blister packs is that they are easy to use. Each tablet or capsule is in a separate blister, so that people can easily take the right amount. They can just pop the tablet out of a pack and don’t have to open a big bottle or pouch. This is especially useful in the case of elderly patients or patients who may have problems in managing their medications. The packaging also typically comes with clear labelling, which displays significant information such as its expiration date and dosage instructions. That helps people understand how and when to take their medication, which is safer for users, and less time consuming.

Aluminium blister pack mean that not only do the medicines remain fresh, they are also user-friendly and friendly to the environment. Hanlin Pharmaceutical Packaging is like a lot of companies in that it has spent the better part of a decade trying to figure out how to make its packaging more environmentally friendly. Blister packs are easily recycled after use, and include aluminum material. This is beneficial not only in waste reduction, but also promotes a healthier planet. Pharmaceutical companies can thus help save the environment while providing superior quality products to their customers by utilizing aluminium blister packs.

How Aluminum Blister Packaging Minimizes Product Waste During Distribution?

So aluminium blister packaging makes sense if you are trying to cut down on waste from transporting your medication. A big reason for that is because the packaging keeps every single tablet or capsule in tact. Products can also rumble around during transit and without sturdy packaging, pills can break or be crushed. When that happens, they cannot be sold and become waste. But with our aluminium blister packs, each tab is individually sealed in its own pocket so they remain protected and ready to take. This results in less product waste during shipping, which is good for companies and saves money.

One other method that aluminium foil blister packaging helps reduce waste is by ensuring that the consumer takes the correct amount of a medicament. It’s easy to lose track of how many pills you’ve taken or how many are left when medicines are packaged in bottles. This might result in unused or expired tablets being discarded. The beauty of blister packs is they are nicely labeled and separated by doses. Users are able to take just what they need, increasing the likelihood that medicine won’t be thrown away. This not only is good for the environment because it reduces waste, but also allows patients to receive the full benefits of their medication without worrying about taking too much or too little.

In addition, enterprises such as Hanlin Pharmaceutical Packaging are always seeking ways of enhancing blister packaging. Thanks to modern technology, they are able to develop packs that are more convenient and easier to open. Less time and fewer returns are spent on distribution, which translates to more winners at the end of the line! In general, the application of aluminum blister packaging in the pharmaceutical industry is very significant. It keeps products from spoiling, preventing waste and making sure drugs get to patients effectively and safely.

Table of Contents

- Why Barriers Matter to the In-use Shelf Life of Tablets?

- How do pharmaceutical blister packs protect against light and moisture?

- Wholesale Where to Get Premium Aluminium Blister Packs?

- Why Choose Pharmaceutical Aluminium Blister Packs?

- How Aluminum Blister Packaging Minimizes Product Waste During Distribution?

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS

KK

KK

UZ

UZ