Suppositories absolutely an application with several advantages over other forms of medicine. These medicines and that can be small inserted into the rectum, where they dissolve and deliver medicine straight into the bloodstream. Hanlin Pharmaceutical Packaging suppository packaging is vital for maintaining these medicines and that can be tiny, safe, and effective.

Suppository packaging has seen advancements over the years. Formerly, Hanlin Pharmaceutical Packaging suppository foil were often covered with plastic or foil and are not really user-friendly. But, today's suppository packaging is much more user-friendly and innovative. One advancement that is current suppository packaging could be the use of air-tight blister packs, that assist to raise the shelf-life related to medication and guarantee its effectiveness.

Suppository packaging is essential for ensuring the safety of patients. The packaging of suppositories has to be made to prevent accidental ingestion of small children and must certainly be tamper-proof to stop contamination. Also, Hanlin Pharmaceutical Packaging alu foil packaging same with the suppository packaging must indicate the best dosage and directions to be used, making it simple for small kids and adults to utilize the medicine properly.

Utilizing packaging of suppository simple and easy. Before placing the suppository, you need to wash both tactile hands and clean the place that is rectal. Then, unwrap the insert and medication it carefully in the rectum use that is making of little finger or an applicator. Be sure to follow any instructions that can be certain by the healthcare provider for appropriate usage and dosage. Hanlin Pharmaceutical Packaging alu alu blister packaging also a packaging product that surely will help you.

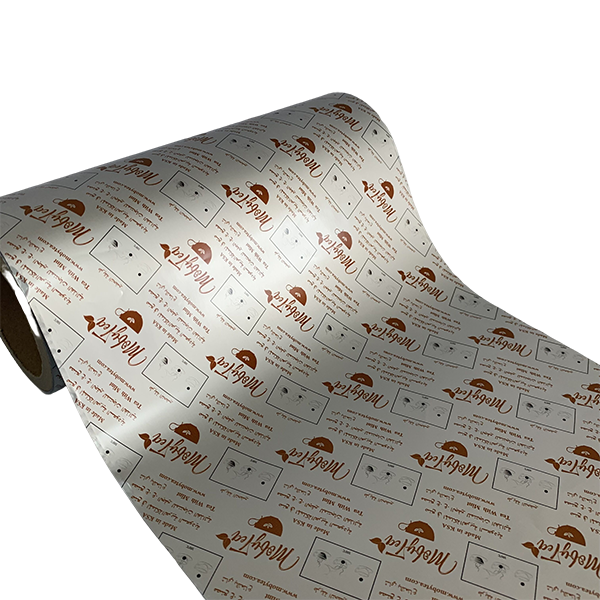

The standard of suppository packaging is key to guarantee the medication's safety and effectiveness. Like the Hanlin Pharmaceutical Packaging foil blister packaging and suppository packaging must be free of certainly any defects that may enable dampness, air, or other contaminants to enter, since this make a difference to the medication's effectiveness. Quality control measures must also be in position all of the time to make sure that the medicine within the packaging is connected with quality this is certainly highest.

1600 square-meter GMP clean workshop situated adjacent Chinese Medicine City. GMP introduced Suppository packaging computer-controlled automatic production lines both domestic and foreign markets, well perfect testing equipment. Company highly-skilled technical team an intelligent management team. This ensures high level reliability product quality, and broad selection of high-quality products services.

Company, established 1995, primarily focused production, sales and study of Suppository packaging, pharmaceutical and packaging materials. Company certified China Food and Drug Administration International Quality Management System ISO9001:2008. Also holds nine packaging registration certificates.

After many years hard work and dedication, quality products has become stable. Over 80 countries Suppository packaging Australia, Italy, United States, Togo, and United Kingdom, export products. UZ, France, Vietnam, Malaysia, Nigeria, Canada, Mexico, etc.

Suppository packaging forward future We will keep upholding "quality more important everything" business ethos, continuously improve our image as brand and keep pace with worldwide trend developing pharmaceutical packaging and constantly strive improve and develop, order provide you with better and more efficient packaging products.